Smart Manufacturing Startup Builds AI OS for Industry 4.0

Table of contents

Smart manufacturing. Industry 4.0. Smart factories. Industrial Internet of Things (IIoT). Manufacturing on demand. The list of buzzwords around how the world will completely digitize the manufacture of every widget imaginable goes on and on. These factories of the future will link every machine and robot, each mapped down to the micron in a cloud-based digital twin. AI algorithms will automate the manufacturing process from end to end, with technologies like 3D printing taking on an outsized role. At least that’s what they tell you in the slide decks. A startup called Oqton is angling to be a key player in the industry 4.0 market with its own smart factory operating system (OS) built around additive manufacturing.

Smart Manufacturing Startup

Founded in 2017, Oqton claims San Francisco as its birthplace but Ghent, Belgium serves as the company’s headquarters. It suddenly popped on everybody’s radar this month after raising a $40 million Series A in its first publicly disclosed fundraising.

Most of the names on the investor list will be unfamiliar outside of certain geographies or manufacturing circles, but there are a couple of notable individuals on board. For example, the CEO of Autodesk (ADSK), a $60-billion-plus software company originally known for a design and drafting application called AutoCAD, is a fan. There’s also a guy named Dries Buytaert who 20 years ago developed Drupal, one of the most popular website content management systems not called WordPress. And there’s Sandvik (SAND.ST), a Swedish engineering firm with revenue of more than $12 billion in 2019.

So what is Oqton doing to gain the confidence of these and other investors? In effect, the company has produced a smart manufacturing cloud-based platform that runs a job from design to production to certification – and everything in between.

The company has built in a number of algorithms that automate and optimize the entire process, while enabling the system to continuously learn and get better at making the best widget as expediently as possible. Oqton claims that in some of its key verticals (for example, jewelry and dental) it has already achieved total automation, which has decreased costs by up to 30%.

Smart Manufacturing Using AI

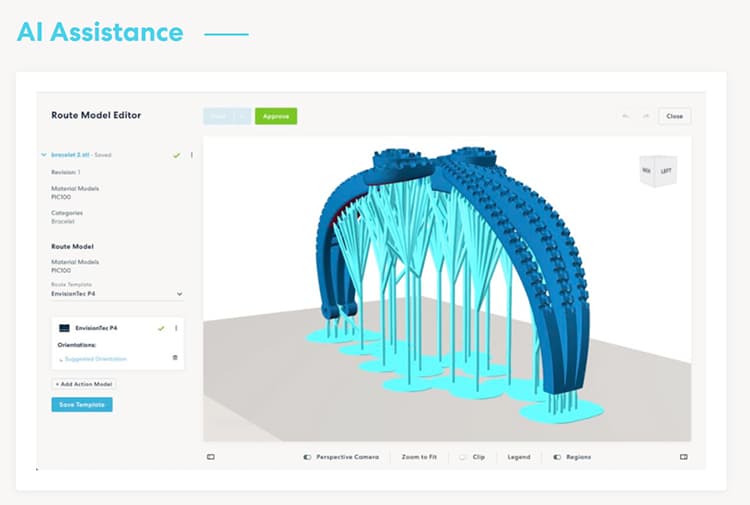

Let’s follow the “digital thread,” as Oqton calls it, to see how AI is used in each phase of its smart manufacturing platform, which can also integrate other kinds of traditional production technologies like welding.

- Design: The software automatically classifies parts based on geometric and production data, and uses AI to continuously refine classification accuracy. Algorithms also go to work to produce the most optimal supports for additive manufacturing in terms of strength and weight.

- Prepare: AI is used to orient parts for best production results.

- Simulate: This includes not just manufacturing but modeling the actual costs of each widget, which is continuously improved as AI learns from historical production cost data. An accurate estimate. How novel!

- Scheduling: Yup, manufacturers can also find value-added tasks for the 330,000-something planning experts in the United States thanks to Oqton’s AI planning tool.

- Monitor: As we’ve covered in other articles about IIoT, AI algorithms are used to monitor machines in real-time using historical data to detect anomalies.

- Analyze: Another function under IoT where the system creates customized reports and other products from sensors and other data.

- Trace: The digital thread that maintains all the production data.

- Finish: Post-processing features like a built-in, fully autonomous robotic control for removing the support structure from the final 3D-printed widget.

- Inspect: See below.

- Certify: There’s probably AI in there somewhere, but you probably get the point by now – Oqton is trying to perfect a turnkey automation platform for smart manufacturing, with 3D printing as the primary production technique.

A Piece of Hardware

While Oqton is all about the software, it has developed an inspection machine that conducts a 3D analysis of parts with an accuracy of 30 micrometers, which is a fraction to the thousandth place of an inch. Wee friggin’ small. In just seconds, the machine identifies any design deviations, such as problems with dimensions, curvature, or color, among others, for widgets up to 20 inches in size.

And, of course, algorithms help improve results over time, especially for testing of specialty parts.

Conclusion

We wrote about the specific topic of manufacturing-as-a-service just last month, as part of the continued maturation of the 3D printing industry from mainly a side hustle for manufacturers to mainstream adoption. The fact that Oqton could land $40 million certainly speaks to that thesis, even if the market is generally going apeshit and flinging feces and 3D printing stock prices higher. We know automation and anything that keeps people perpetually underemployed sheltered in place is trending with investors, so maybe it was an easy sell for Oqton.

In terms of market potential, there are some smart manufacturing reports out there but nothing that we would trust, with estimates running from $10 billion to nearly $400 billion in the next few years. Perhaps a better measure of where this could go for a company like Oqton is the example of one of its key investors, Autodesk, which now sells software that includes not just architecture and engineering, but genetic engineering and even media. That begs the question: What are some of the software companies that will dominate the Fourth Industrial Age? It’s definitely too early to forecast that for Oqton, with investor Sandvik probably its biggest client, at least in terms of stature.

Which 3D printing stocks are we holding in The Nanalyze Disruptive Tech Portfolio? Become a Nanalyze Premium annual subscriber to find out now.

Sign up to our newsletter to get more of our great research delivered straight to your inbox!

Nanalyze Weekly includes useful insights written by our team of underpaid MBAs, research on new disruptive technology stocks flying under the radar, and summaries of our recent research. Always 100% free.