Sustainable Lithium Batteries from Sweden’s Northvolt

Table of contents

Back in 1969, the Apollo lunar module used 29 volt, 400 amp hour batteries during its historic moon landing. The cells responsible for the safe landing and subsequent return of the crew were 60 kg beasts with plenty of built-in redundancy to ensure the success of the mission. Today, you can order a battery pack with similar performance for a few bucks off Alibaba. Battery technology has come a long way, and today it’s lithium-ion batteries that power our phones, laptops, cars, and even our houses. Still, we have a long way to go towards achieving the sort of functionality needed to address some of the bigger problems.

If we’re going to wean the earth’s population off fossil fuels, we need to address the energy storage problem. Sustainable resources like the sun and wind depend on surface weather and produce electricity at a different time than when a majority of it is consumed. In the case of solar, you need to store all that sunshine energy for when people need it the most – nighttime. The ability to store large amounts of energy and release it when needed is one giant use case for batteries. Another is electric cars which need high-performing batteries to become viable alternatives to their gasoline-powered siblings. All of this translates into a rapidly growing market for batteries – CleanTechnica reported a 9% growth in battery production pipelines in the single month of March 2019.

The Dirty Secret of Batteries

Many startups are developing new cell technologies or building battery factories and venture capital is happy to finance development with major funding rounds. Batteries may be a key part of a clean energy future but their manufacturing processes still rely heavily on energy gained from fossil fuels. Ironically, some speculate that the move towards automobile electrification may actually do more damage to the environment. Building a car battery in Germany or Poland, countries which still have coal-heavy industries, would emit up to 74% more carbon dioxide than producing an efficient conventional car. According to Berylls, a Munich-based automotive consultancy, an average German car owner can use a gas-powered vehicle for three and a half years before a Nissan Leaf with a small battery would beat it on CO2 emissions. On the other hand, electric cars in Norway generate 60% less emissions than the most efficient gasoline vehicles over their lifetime because it is hydro-electric energy that powers the national grid.

Emissions depend on where a battery is made, how it is made, and where the electricity is sourced from, so it is key to efficiently control all three factors in order for batteries to be “sustainable.” As investors, we’re not interested in subsidizing the world’s problems so “sustainability” has to translate into profits. In the case of sustainable batteries, that’s a “feature” that we can now charge a price premium for. Better yet, build a sustainable battery and sell it at the same price as competing solutions. Guess which battery will make an easier sell for the C-suite who desperately wants to improve their ESG score so they can be praised by all the armchair CEOs on Twitter? The answer is a sustainable battery, the likes of which is being developed by Northvolt.

An Enterprise Based on Sustainability

Founded by two former Tesla executives in 2016, Swedish startup Northvolt has raised a whopping $1.1 billion from investors like the European Investment Bank, Volkswagen, BMW, Siemens, and Goldman Sachs to create the world’s greenest battery manufacturing operation.

Update 06/09/2021: Northvolt has raised $2.8 billion in funding to expand capacity in their Swedish factory from 40 gigawatt-hours to 60 gigawatt-hours. This brings the company’s total funding to $6 billion to date.

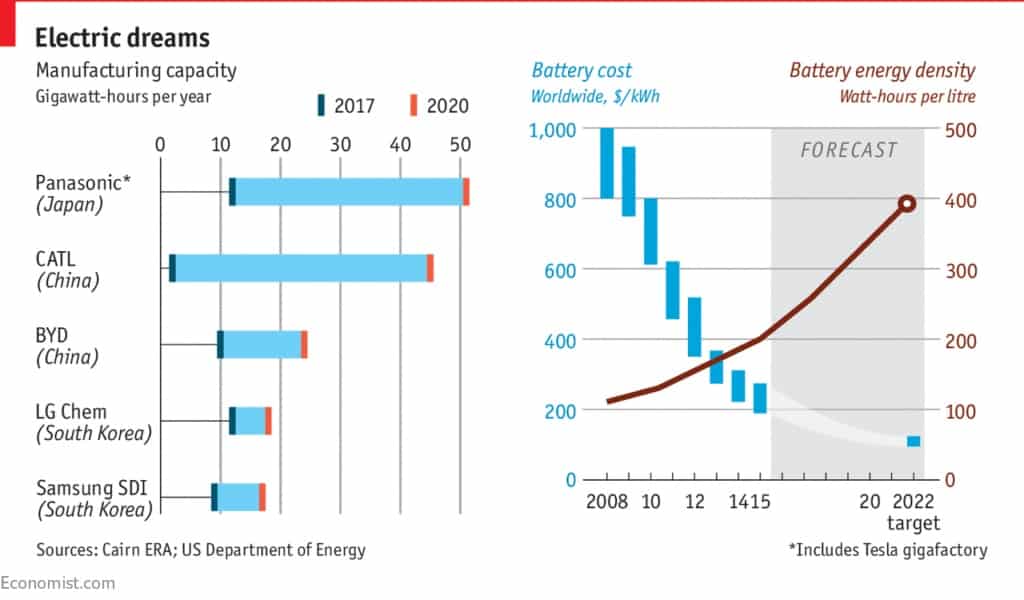

The company plans to build a large-scale factory in the north of Sweden that will be able to produce 32 GWh worth of capacity each year, making it one of Europe’s largest battery factories, and making Northvolt a player in the big leagues. The term “gigawatt-hours per year” metric provides a convenient way to measure battery production across various manufacturers, all of which are producing different battery configurations:

The Northvolt gigafactory is set to open in 2020 and will run entirely on hydropower producing close to zero emissions. It will also be responsible for materials preparation (the company will create its own chemical mixes for the anodes and cathodes in the batteries) and recycling, both of which will reduce the environmental footprint of the batteries. The gigafactory is only one part of Northvolt’s vision though. The company aims to cover most of the battery value chain with its activities, including transportation, lifecycle management, recycling, and building large scale energy solutions. This vertical integration will let Northvolt exercise control over the sustainability of its processes, and provide economies of scale as well.

The startup has already opened a factory to build battery modules and energy storage systems in Gdansk, Poland, that currently has an output of 10,000 modules per year. The Polish installation is only responsible for the assembly of custom systems from battery cells made in Sweden, which ensures energy-intensive cell manufacturing processes are kept at Northvolt’s sustainable location. A research facility and smaller demonstration unit near Stockholm will follow later this year, that will be used to work on customized products with customers. These plants will allow Northvolt to develop cells tailored for specific applications and modular battery systems for large-scale use. This way, the company will be able to serve markets with diverse battery requirements, ranging from home appliances to industrial machinery and grid storage.

Northvolt’s well-rounded hardware offering is complemented by consultancy and data services as well. The startup works with customers on electrification planning and strategy to determine short, medium, and long-term needs for cells and connectivity related to a business case. The team also offers data solutions like tracking battery cell usage patterns and lifecycle to provide predictive maintenance, monitor cost of ownership, and manage performance.

Controlling the Product Lifecycle

Northvolt aims to fully control its sustainability processes the same way it tries to serve all of its potential client segments. The startup’s green initiatives don’t stop with manufacturing, but cover complementary activities like transportation, used battery retrieval, and recycling as well. For example, Northvolt helps its mining partner Epiroc to electrify its fleet of underground vehicles, making its own supply chain greener in the process. Fleet electrification means Epiroc has to spend less on ventilation to eliminate diesel exhaust from closed confines in mines, and Northvolt gets to sell them the batteries that make it all work. What Northvolt does is to solve an environmental problem in an economically viable manner. The same applies to recycling. When end-of-life batteries are dismantled, the raw materials can find their way back into production lines saving part of the resource cost.

Future Pipeline

While executing on its ambitious plans to build their giant European gigafactory, Northvolt is already planning its first major expansion. The startup is looking to build another gigafactory with 16 GWh per year capacity in a joint venture with its major investor, Volkswagen. The carmaker has announced it will invest about $1 billion in joint activities with Northvolt, part of which will go towards the construction of this new manufacturing plant in Germany, one that will be developed with the same level of commitment to renewable energy. Construction is expected to begin in 2020 at the earliest, and cell production at the factory will start late 2023 or early 2024. The deal also involved Volkswagen acquiring a 20% stake in Northvolt with a seat on the startup’s board.

Conclusion

Northvolt has enough financial support to take on the large Asian battery producers with a “sustainable battery” that comes from a region of the world where sustainability is simply expected – at a cost of course. Vertical integration will allow Northvolt to control costs tightly which means they should come to the market with a competitive price along with the added bonus of increasing a company’s ESG scores. The caliber of investors help validate the technology and business model but it all comes down to execution.

Sign up to our newsletter to get more of our great research delivered straight to your inbox!

Nanalyze Weekly includes useful insights written by our team of underpaid MBAs, research on new disruptive technology stocks flying under the radar, and summaries of our recent research. Always 100% free.

The Swedish battery cell manufacturer Northvolt wants to go public. The intended listing is to take place in 2022 or 2023 and bring the company a valuation of 20 to 30 billion euros.

This was reported by Manager Magazin with reference to company circles. Northvolt is currently building a battery cell plant in Skellefteå, Sweden, which is also known as Gigafactory 1 of the Volkswagen Group. Although Northvolt operates the plant itself, the premium cells planned there, whose cathodes will have a high nickel content, are primarily intended for Volkswagen subsidiaries Audi and Porsche.

Northvolt is now apparently seeking an IPO for the capital-intensive development of cell production. Recently, the start-up has already completed several capital increases, which have reflected great investor interest. In June, Volkswagen announced that it had invested a further 620 million US dollars (around 500 million euros) in its battery partner. Volkswagen’s additional investment was part of a total of 2.75 billion US dollars (around 2.3 billion euros) in a new financing round for the Swedish battery company.

That news seems premature if the listing is to take place in 2022 or 2023. Thank you for posting!

Swedish battery manufacturer Northvolt announced that on December 28th, it successfully produced the first lithium-ion battery cell to be designed, developed, and built completely in Europe by a homegrown company.

“Last night, the commissioning of the Northvolt Ett gigafactory in northern Sweden led to the assembly of the first battery cell,” Northvolt wrote. The company’s factory, located in Västerås, Sweden, is the first factory in Europe to have a cell that has been “fully designed, developed and assembled at a gigafactory by a homegrown European battery company,” the company added.

The production of the cell is a massive milestone for Northvolt, which has been working to get its gigafactory up and running since 2017. The company said the cell is of a prismatic cell format, which consist of large sheets of anodes, cathodes, and separators sandwiched, rolled up, and pressed to fit into a metallic or hard-plastic housing in cubic form, according to AllAboutCircuits.

They produced a battery. Awesome. Next milestone we’ll be watching for is meaningful revenues.