10 Startups Working on Robotics for Manufacturing

Table of contents

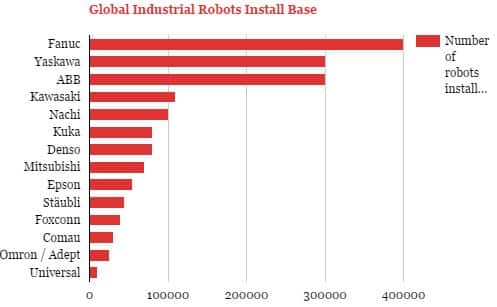

When we think about bringing manufacturing back to the USA, we may need to think about that in the context of robotics for manufacturing. As we discussed before, Asian countries like Japan are dominating the industrial robotics space (Source: Robotics and Automation News):

In several recent articles, we looked at the large industrial robotics players listed in the U.S. here and here. We also explored a number of industrial robots that can help you around the warehouse. Now we’re going to take a look at startups that are working on robots for manufacturing. Startups like Rethink Robotics, are creating intelligent robots for manufacturing that actually work alongside humans and learn from them. And they look kind of cute so you won’t get too pissed off at them when they steal your job free you up to do more value-added activities.

Speaking of job dislocation, there are now robot factories in Japan called “lights out” factories where they only turn on the lights once a month when the humans come around for routine maintenance. Here are 11 startups that may be powering the “lights out” factories of tomorrow.

Smart Robotics

Founded in 2015, Dutch startup Smart Robotics (SR) has taken in an undisclosed amount of funding to develop modular robots that can be configured to do different tasks in manufacturing and logistics. The unique quality of these robots is their flexibility. They can do assembly line work, product sorting, machine loading, quality control and packaging.

SR calls themselves an employment agency for robots, as the product is not only for sale but for rent as well, acting as a temp worker in your manufacturing plant or warehouse. SR offers software upgrades, maintenance and reconfiguration assistance as support services, which allows your new temp hire to lend a hand where you need it most.

Quotient Kinematics Machine

QKM, or Quotient Kinematics Machine, is a Chinese startup which was founded in 2015 and has received $4.6 million in total funding so far. QKM serves the Chinese market (their website doesn’t have an Engrish version) with lightweight and high-performance pick-and-place robots. Robots they’ve launched so far can be seen below:

These robots can work in precision machinery, chemical and pharmaceutical manufacturing, sorting, assembly and packaging.

Grabit

Founded in 2013, Californian startup Grabit has received $21 million in total funding so far. Their investors include ABB, Nike, NTT Docomo and Samsung. Grabit serves manufacturing industries like footwear, apparel, automotive, aerospace and electronics, as well as warehouse logistics functions by equipping robots and automation systems with their proprietary electroadhesion grasping technology.

Electroadhesion is based on the same principle as static cling when you take out clothes from a drier. It is precise, has a light touch, and consumes much less power than competitors’ vacuum based grasping methods. How much less power? The amount of energy required to run a large robotic vacuum gripper system for one week could power a Grabit gripper for over five years. That’s a pretty easy sell.

Update 08/03/2018: With a previous minority stake acquisition in Grabit, shoe brand Nike utilizes Grabit’s Robotic arm that uses static electricity to put together their shoes. According to Bloomberg, Nike has installed about a dozen Grabit machines in their factories in Mexico and China.

Systemantics

Founded in 1995, Indian startup Systemantics has taken in $1.4 million in total funding from Accel Partners and Blume Ventures. Their 4-axis robotic arm is a platform that allows positioning horizontally with a swivel and lift mechanism for vertical motion and rotation.

This freedom of movement makes it perfect for fastening multiple screws, or for soldering chip-sets. According to the Systemantics website, they’ve already shipped this 4-axis platform to a client for production, and are currently working on developing a 6-axis advanced version.

Life Robotics

Coro is built for small manufacturing spaces, where traditionally bulky manufacturing robots wouldn’t fit, to work alongside people. It can learn motions using a 3D mouse or a gamepad without the human operator having to utilize complex programming skills.

Update 08/03/2018: LifeRobotics took in $9 million from a Series B round last November of 2016, one that quickly followed a Series A round of $4.4 million a few months prior. The latest funding will be used to scale mass production and sales of the cobot and improve follow-up services for their clients. Currently, LifeRobotics already has a total funding of $13.4 million.

RB 3D

Launched in 2001, French company robotics startup RB 3D has attracted investments totaling $5.3 million to date. The Company specializes in strength assistance and has 2 product lines: cooperative robot (cobot) arms and an exoskeleton suit, which is a topic that we were digging into in a recent article. RB 3D cobots are human controlled arms which assist with heavy lifting, and have 1-7 axis (degrees of freedom), in motorized and non-motorized versions.

Besides handling loads, they are also used for grinding, sanding, screwing, drilling and clipping. The exoskeleton Hercule v3 pictured above is for strength assistance. It has 2 legs and a front platform that can carry loads of up to 100kg (that’s 220 pounds for all you Yanks out there). It can manage 10-degree slopes, stairs, sitting and squatting positions. Although the current version is said to be developed for civilian use, military application is an obvious next step for RB 3D.

GettinG Robotika

Different cells are available for large, medium and small parts, all of them equipped with a scanner to map the area which needs smoothing (this is where their tools become more “robot” and less “automation machine”). Pictured above, the robot has 5 axis of free movement. Helping heavy industries like wind power, automotive, cement and mining, their high degree of specialization and +40% productivity claim are what makes them an easy sell.

Ready Robotics

Founded just last year, Baltimore, Maryland startup Ready Robotics has taken in seed funding of $3.5 million. While industrial robotics has been helping high-volume manufacturers for the past decades, Ready Robotics is on a mission to help small-scale manufacturers with an easy-to-use, collaborative system based on technology licensed from The Johns Hopkins University.

The main selling point of their TaskMate robot is quick deployment. It targets small-scale manufacturers that operate in apparel, metal bending or woodworking industries. In April 2016, their plug-and-play technology called CoSTAR won the KUKA Innovation Award. Kuka is a giant industrial robotics company, so this validation shows Ready Robotics that they’re on the right path.

Update 08/03/2018: Ready Robotics received an additional $15 million in a funding round late last year led by Drive Capital which will be used for operations expansion. This brings the company’s total funding to $18.8 million thus far.

Workforce

Founded in 2012, Blue Workforce is a Danish startup that has taken in an undisclosed amount of funding so far. Their Ragnar (awesome Viking name!) pick-and-place robot platform is made up of different building blocks and can be customized to fit individual requirements like fixed, steady, random or conveyor input and output. Open-source software, a lightweight design, the fact that it’s portable, and a proprietary gripping technology should make this flexible robot an easy sell.

They even have a webshop where you can actually pick and choose all the parts and order the robot which you’ve configured, all for a cost that is 4-10 times cheaper than the competition. Blue Workforce recently acquired Coppelia Robotics, a virtual robot simulator, to assist in their development efforts.

SoftWear Automation

The Company’s “Sewbots” (pictured above) are capable of tracking individual threads in textiles, and also detect fabric defects and individual variations of the finished product. This allows for more precision and better quality control for finished garments in an industry where significant costs are attributed to waste.

Update 08/03/2018: Softwear Automation took in an additional $4.5 million in financing from an existing investor, CTW Venture Partners, June of last year. The company now has a total funding of $7.5 million so far.

Conclusion

We’ve introduced you to “sewbots” and “cobots” along with 8 other startups working on interesting applications of robotics for manufacturing. The themes we see throughout these startups are plug-and-play implementation, flexibility built on modules, and making robots that are small and light. We haven’t had any real robot IPOs yet so maybe one of these companies can lead the way so retail investors can get some exposure to the fast-growing application of robotics for manufacturing.

Sign up to our newsletter to get more of our great research delivered straight to your inbox!

Nanalyze Weekly includes useful insights written by our team of underpaid MBAs, research on new disruptive technology stocks flying under the radar, and summaries of our recent research. Always 100% free.